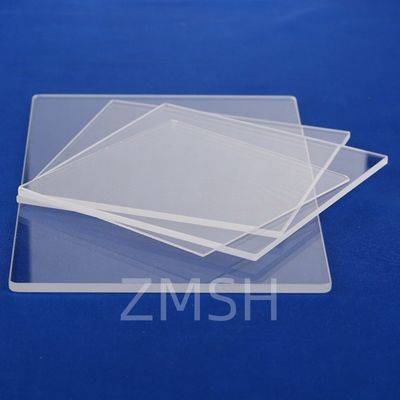

Fused Silica Quartz Glass Window SiO2 UV-Infrared Transmitting, Laser

Datos del producto:

| Place of Origin: | China |

| Nombre de la marca: | ZMSH |

Pago y Envío Términos:

| Minimum Order Quantity: | 2 |

|---|---|

| Delivery Time: | 2-3 weeks |

| Payment Terms: | T/T |

|

Información detallada |

Descripción de producto

Fused Silica Quartz Glass Window SiO2 UV-Infrared Transmitting, Laser

Product Introduction

The SiO₂ quartz glass plate, also known as a quartz window, quartz substrate, or transparent silica sheet, is an amorphous material manufactured from high-purity silicon dioxide. It exhibits outstanding optical transmittance, thermal resistance, extremely low thermal expansion, excellent dielectric strength, and exceptional chemical inertness. Designed to operate under extreme temperature and aggressive chemical conditions, quartz plates are indispensable in advanced technological sectors. Based on purity and applications, they are classified into optical-grade, semiconductor-grade, and industrial-grade variants.

![]()

![]()

Manufacturing Principle

The manufacturing of quartz glass plates involves the following steps:

-

Raw Material Preparation: High-purity natural quartz sand or synthetically vapor-deposited SiO₂ is used, with metallic impurities controlled below 1 ppm;

-

Melting & Forming: Electric furnace, flame fusion, or plasma melting is used to melt the raw quartz at over 2000°C, followed by casting or pulling into bulk or cylindrical shapes;

-

Annealing: To relieve internal stress, the quartz plates undergo slow annealing around 1000°C for dimensional stability;

-

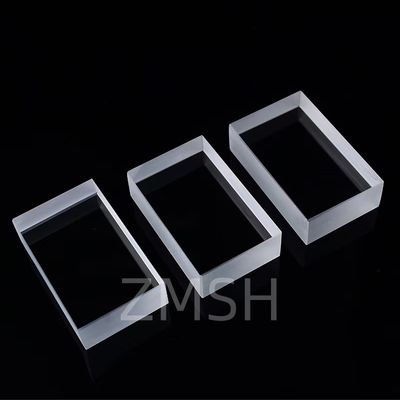

Cutting & Grinding: Diamond tools are employed to slice quartz blocks into desired dimensions with precision;

-

Polishing (Optional): Optical-grade quartz is polished to atomic-level smoothness (Ra<1nm), on one or both sides;

-

Cleanroom Packaging: Final cleaning and packaging are done in ISO-certified cleanrooms to suit semiconductor environments.

Technical Specifications

| Item | Range |

|---|---|

| SiO₂ Purity | ≥99.99% (Semiconductor-grade) |

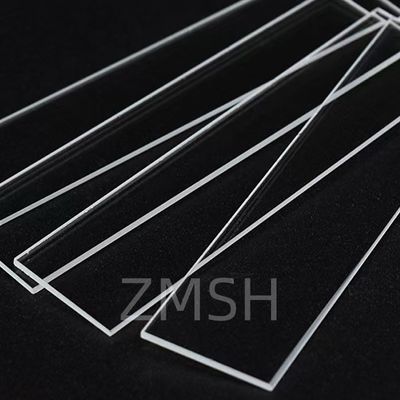

| Dimensions | 5mm × 5mm to 600mm × 600mm |

| Thickness | 0.3mm – 30mm (customizable) |

| Surface Roughness | Ra < 1 nm (optical polish) |

| Flatness | λ/10 @ 633nm (high-precision) |

| Thermal Expansion | 5.5 × 10⁻⁷ /℃ |

| Operating Temp | Continuous <1100°C, short-term ≤1200°C |

| Light Transmission | >90% (190nm–2500nm) |

Application

Thanks to its exceptional material properties, quartz glass plates are applied in:

-

Semiconductor Industry: Photomask substrates, cleaning carriers, wafer holders, plasma etching windows;

-

Laser & Optics: UV windows, IR windows, cavity optics, lens mounts;

-

Aerospace Optics: High-transparency shields, sensor viewports;

-

New Energy: Laser welding shields, hydrogen fuel cell ports;

-

Chemical Labs: Acid/base-resistant observation windows, reactor viewports.

![]()

![]()

Quartz vs. Other Glasses

| Property | Quartz Glass | Borosilicate | Soda-Lime Glass |

|---|---|---|---|

| SiO₂ Purity | ≥99.99% | ~80% | ~60% |

| Heat Resistance | Excellent (>1100°C) | Moderate (~500°C) | Poor (<300°C) |

| UV Transparency | Excellent (from 185nm) | Moderate | Poor |

| Thermal Expansion | Very Low | Medium | High |

| Use Cases | Semiconductor, Optics, Aerospace | Labs, Kitchenware | Architecture, Daily Use |

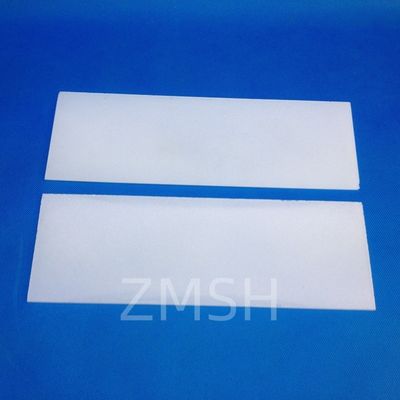

JGS Quartz Glass Classification

The JGS series is a common classification system for optical-grade quartz glass in China. Each type offers different transmission characteristics for UV, visible, and IR light:

| Grade | Name | Key Features | Transmission Range | Typical Applications |

|---|---|---|---|---|

| JGS1 | UV Optical Quartz | Excellent UV transmission from 190nm | 190–2500nm | UV laser windows, photomask plates, UV spectrometers |

| JGS2 | Optical Quartz | Slight UV absorption, cost-effective | 260–2500nm | Visible laser windows, optical equipment, general optics |

| JGS3 | Infrared Quartz | Strong UV absorption, good IR transmission | 260–3500nm | IR windows, thermal imaging optics, detector shields |

FAQ

Q1: Is quartz glass the same as crystal glass?

A: No. Quartz glass is pure amorphous silica, while crystal glass often contains lead oxide and is used for decorative purposes.

Q2: Is quartz plate fragile?

A: While quartz is hard, it's still brittle. Handle with care using gloves and shock-absorbing packaging.

Q3: Can I request drilled holes or CNC machining?

A: Yes. We offer laser drilling, CNC chamfering, and precision edge treatment per your specifications.